Top Tips for Choosing the Best Welding Cable for Your Projects

In the world of fabrication and metalworking, selecting the right welding cable is crucial for ensuring performance and safety. According to a report by Grand View Research, the global welding equipment market is projected to reach $23.57 billion by 2025, with a significant portion of that demand driven by advancements in welding technology and materials. The efficiency of welding cables plays a pivotal role in this growth, as they are essential for conducting electricity effectively, minimizing energy loss, and ensuring optimal weld quality. Furthermore, the International Institute of Welding emphasizes that high-quality welding cables can reduce the risk of overheating and increase overall productivity. As the industry continues to evolve, understanding the properties and specifications of welding cables becomes paramount for professionals seeking quality and reliability in their projects.

In the world of fabrication and metalworking, selecting the right welding cable is crucial for ensuring performance and safety. According to a report by Grand View Research, the global welding equipment market is projected to reach $23.57 billion by 2025, with a significant portion of that demand driven by advancements in welding technology and materials. The efficiency of welding cables plays a pivotal role in this growth, as they are essential for conducting electricity effectively, minimizing energy loss, and ensuring optimal weld quality. Furthermore, the International Institute of Welding emphasizes that high-quality welding cables can reduce the risk of overheating and increase overall productivity. As the industry continues to evolve, understanding the properties and specifications of welding cables becomes paramount for professionals seeking quality and reliability in their projects.

Understanding the Different Types of Welding Cables Available in the Market

When it comes to welding projects, selecting the right welding cable is crucial for ensuring efficiency and safety.

There are several types of welding cables available on the market, each designed for specific applications.

The most common types include rubber-insulated cables, which offer excellent flexibility and durability,

making them ideal for on-site use. Additionally, there are thermoplastic cables, known for their lightweight nature and resistance to abrasion,

which are perfect for environments where mobility is key.

Another important consideration is the ampacity of the welding cable, which determines how much current the cable can safely carry.

This is critical in preventing overheating and potential hazards. Users should also be aware of the insulation type and its temperature rating,

as welding cables often operate in extreme conditions. Understanding these differences will help you choose the best welding cable

suited for your particular project, ultimately optimizing performance and enhancing overall safety in your welding applications.

Factors to Consider When Choosing Welding Cable Length and Gauge

When selecting welding cables, understanding the length and gauge is crucial for ensuring optimal performance in your projects. The American Welding Society (AWS) recommends using a welding cable with a gauge that matches the amperage of your welder. For example, if you're working with a machine that operates at 200 amps, a minimum of 2-gauge cable is recommended. This ensures that the cable can handle the current without overheating, which is essential for both safety and efficiency.

The length of your welding cable also significantly impacts its performance. Longer cables can introduce voltage drops, which may lead to insufficient welding power. According to a study published by the Fabricators and Manufacturers Association, a voltage drop exceeding 3% can negatively affect welding quality and productivity. Therefore, it's advisable to keep your cable length as short as possible while ensuring it accommodates your workspace. Balancing these two factors—gauge and length—will not only enhance your welding results but also extend the lifespan of your equipment.

Evaluating the Insulation Material for Optimal Performance and Safety

When selecting welding cables, evaluating the insulation material is crucial for ensuring optimal performance and safety. The most common insulation materials used in welding cables are PVC and rubber, each offering unique advantages. According to a report by the International Institute of Welding, cables with rubber insulation can withstand higher temperatures and are more flexible, making them ideal for environments that require a degree of mobility. In fact, rubber-insulated cables can operate safely in temperatures ranging from -40°C to 90°C, while PVC cables typically handle up to 70°C.

Moreover, the choice of insulation also impacts not only the durability but also the safety aspects of welding operations. For instance, a study by the American Welding Society highlights that high-quality insulation reduces the risk of electrical failure and enhances resistance to abrasion and chemicals. This is particularly relevant in heavy industrial settings where cables are subject to harsh conditions. Investing in cables with superior insulation materials not only prolongs the life of the equipment but also ensures compliance with safety regulations, which can significantly reduce workplace hazards. Thus, when selecting welding cables, prioritizing the insulation material is essential for both performance and safety.

Key Features to Look for in High-Quality Welding Cables for Durability

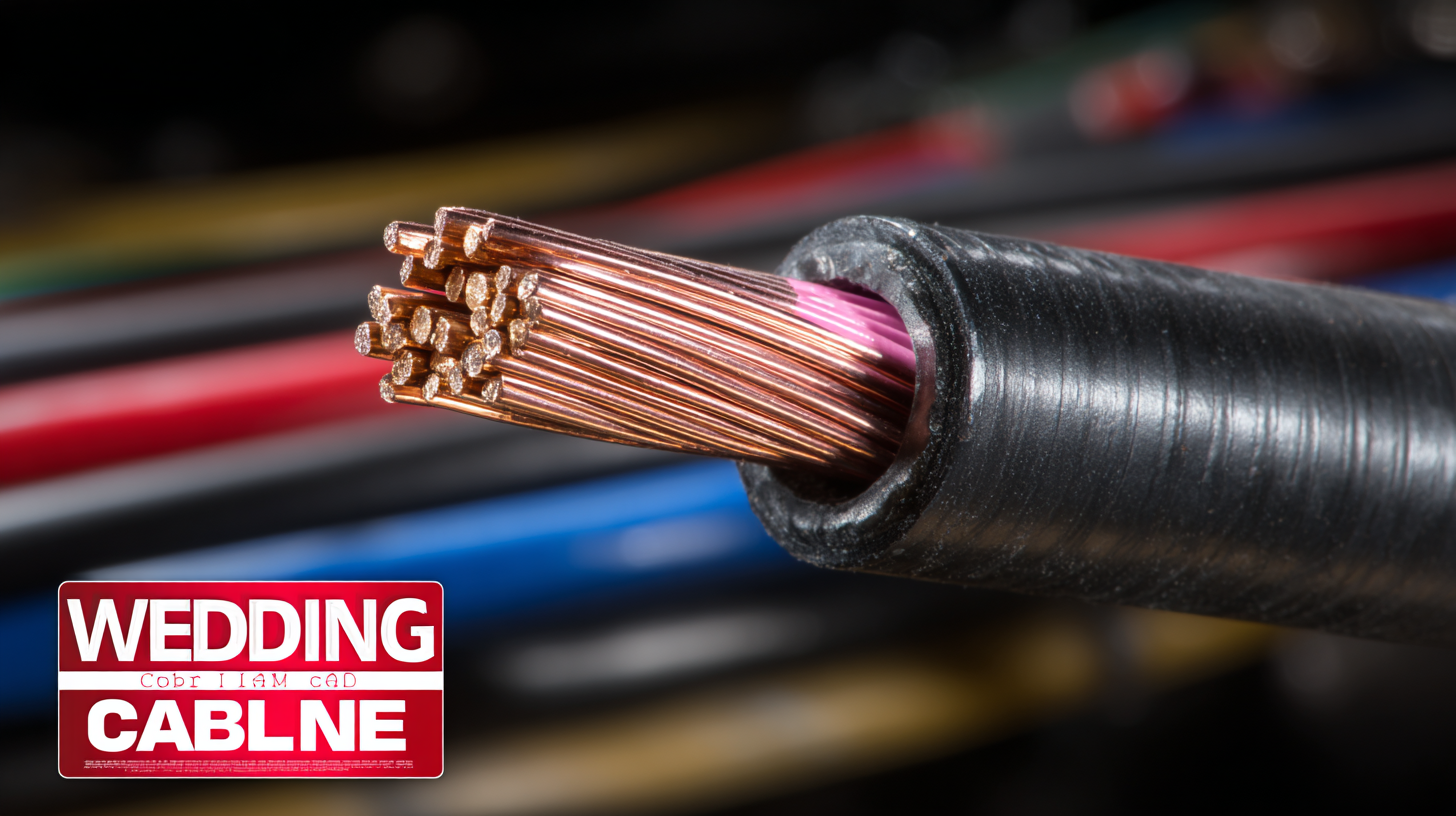

When selecting the best welding cable for your projects, it's essential to focus on key features that ensure durability and reliability. High-quality welding cables should be constructed from materials that can withstand harsh working conditions, such as high temperatures and exposure to environmental elements. Look for cables made from flexible, heat-resistant materials that prevent cracking and allow for easy maneuverability during your welding tasks.

Moreover, consider the cable's structure; multi-conductor designs often provide better flexibility and conductivity compared to single-conductor cables. Insulation plays a critical role in preventing damage and ensuring safety, so opt for cables with robust insulation to reduce the risk of electrical hazards. Pay attention to the voltage rating as well, ensuring that the cables can handle the demands of your welding equipment while maintaining optimal performance and longevity in the field.

Common Mistakes to Avoid When Selecting Welding Cables for Your Projects

When selecting welding cables for your projects, trying to navigate through the vast options can lead to common pitfalls. One of the most frequent mistakes is underestimating the importance of cable gauge. For example, using a cable with an insufficient gauge can cause overheating and inefficient performance. The American National Standards Institute (ANSI) advises that for most welding applications, a minimum cable size of 6 AWG is recommended for up to 200 amps, while larger gauges are necessary for higher amperage.

Another common error is neglecting the cable insulation type. Different welding processes generate various heat levels that require specific insulation materials. Using cables with inadequate insulation could pose safety risks, including electrical short circuits or fires. According to industry reports, rubber and PVC are commonly preferred insulation materials due to their excellent durability and flexibility under extreme conditions.

Lastly, not considering the environment in which you’ll be working can lead to cable damage; ensuring your cables are rated for outdoor use if you plan to weld outside is crucial for longevity and reliability.