Unlocking Excellence: In-Depth Technical Specifications of the Best Low Voltage Cable for Global Buyers

In the rapidly evolving landscape of electrical infrastructure, the importance of selecting the right Low Voltage Cable can never be overstated. With a myriad of applications spanning from residential installations to complex industrial systems, understanding the technical specifications and real-world industry applications of these cables is crucial for global buyers. However, navigating through the varied types available in the market presents its own set of challenges. This blog aims to unlock excellence in the realm of Low Voltage Cables by providing an in-depth analysis of their specifications, exploring successful case studies across different sectors, and addressing common problems faced by users when selecting the best type for their specific needs. As we delve into these aspects, readers will gain valuable insights that empower them to make informed purchasing decisions and optimize their electrical setups.

Types of Low Voltage Cables: A Comprehensive Overview for Global Buyers

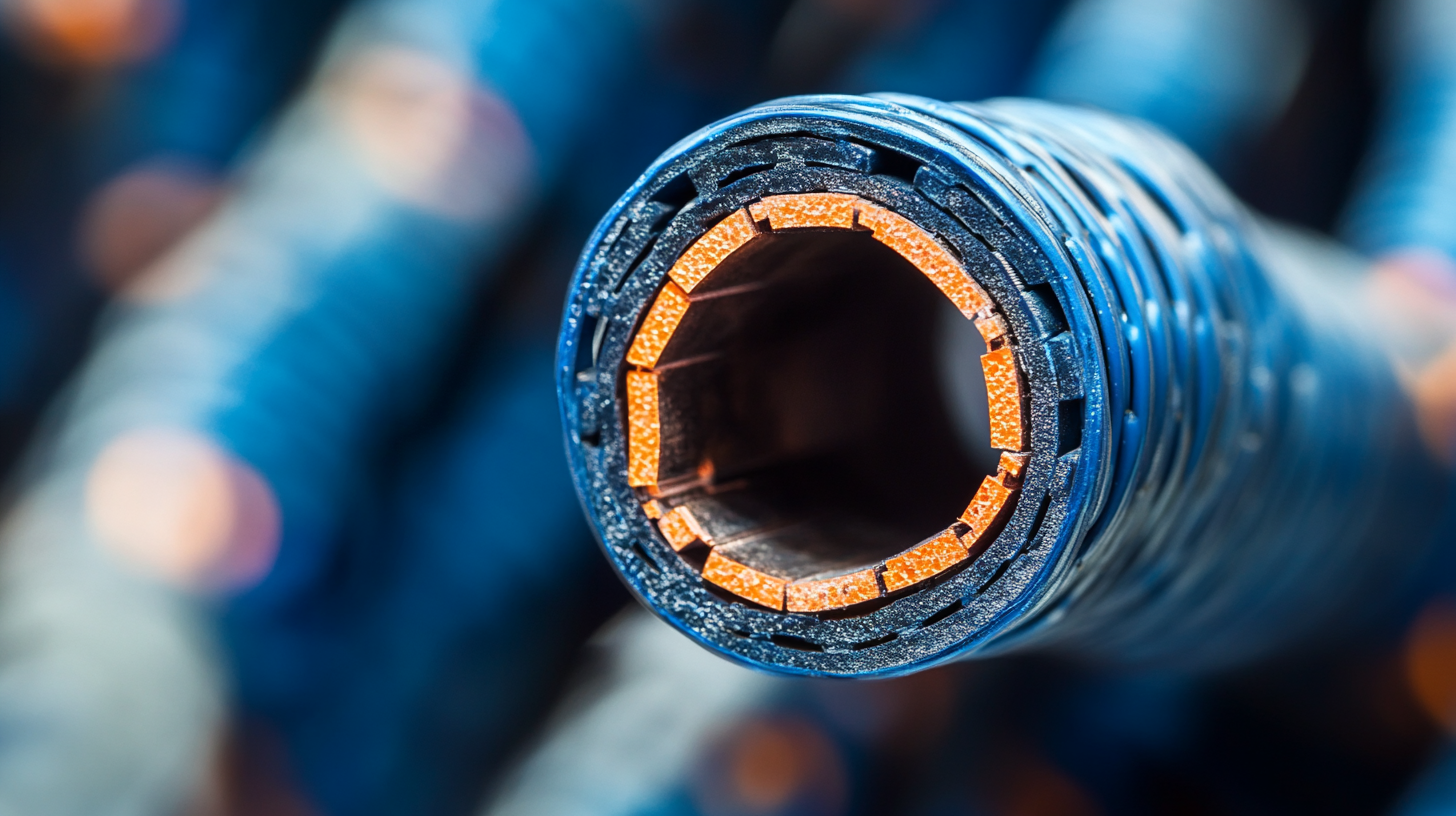

Low voltage cables are essential components in various electrical systems, ensuring safe and reliable power distribution. There are several types of low voltage cables, each designed for specific applications and environments. Among the most common types are the PVC insulated cables, which provide excellent flexibility and resistance to moisture, making them ideal for indoor use. Additionally, XLPE (cross-linked polyethylene) cables are known for their higher thermal resistance and durability, suitable for both indoor and outdoor applications.

Another crucial type is the armored cable, which features additional protective layers to safeguard against physical damage, making them perfect for industrial settings. For communication purposes, twisted pair cables and coaxial cables play a vital role in networking and telecommunications, providing reliable signal transmission without interference. Understanding these different types helps global buyers select the right cable based on their unique requirements, whether for residential, commercial, or industrial installations.

Key Technical Specifications to Consider When Choosing Low Voltage Cables

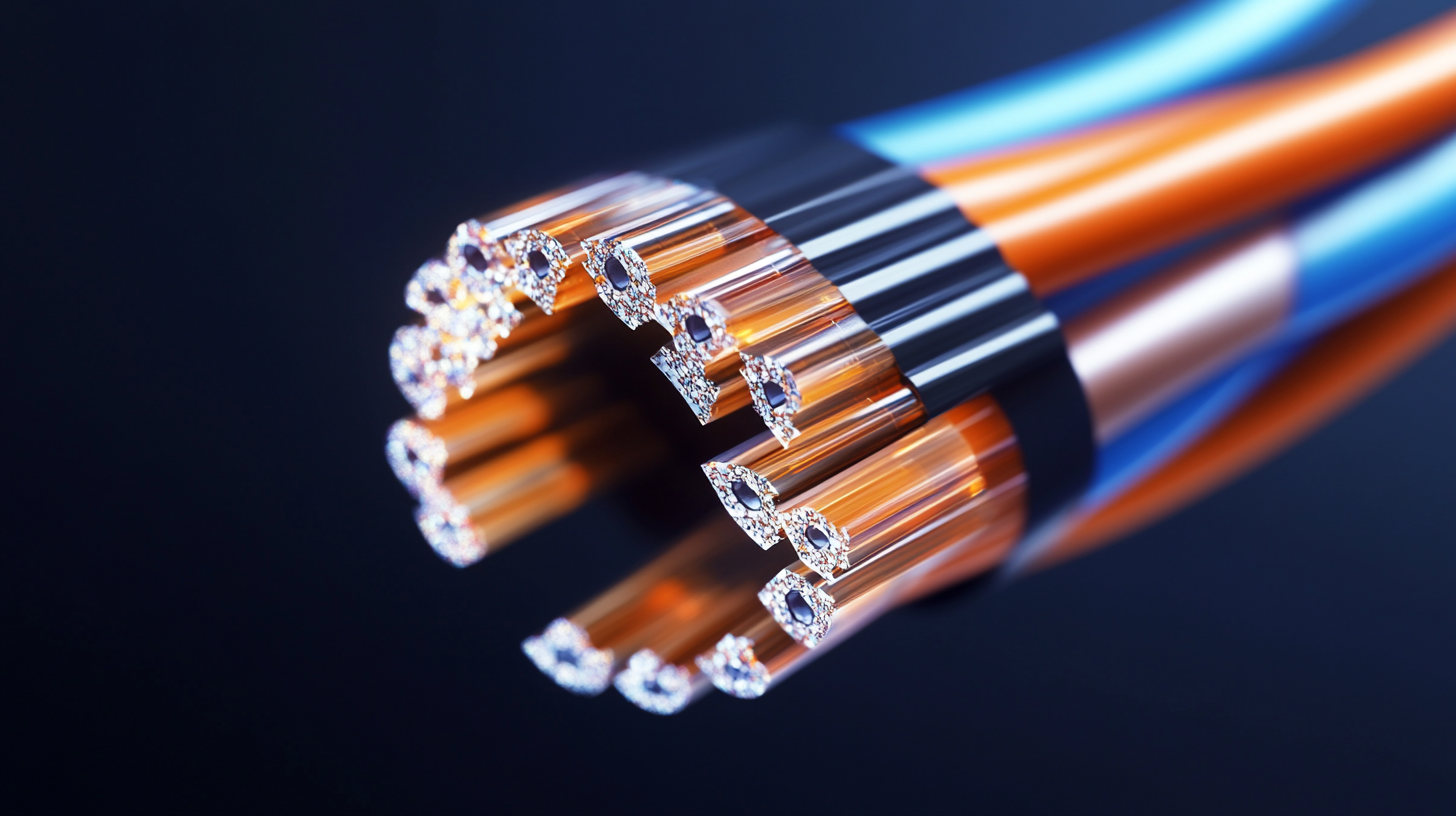

When selecting low voltage cables, understanding key technical specifications is crucial to ensure optimal performance and safety. First and foremost, the cable's voltage rating plays a significant role; it must match or exceed the specific requirements of your application to prevent potential failures. Additionally, the conductor material, typically copper or aluminum, affects both conductivity and flexibility. Copper is preferred for its superior conductivity, while aluminum is lighter and more cost-effective. Buyers should also consider the insulation type, as it impacts the cable's durability and resistance to environmental factors such as moisture and heat.

Another critical aspect is the ampacity, which refers to the maximum amount of electric current a cable can carry without overheating. This specification varies depending on the cable size and insulation type, making it vital to accurately assess the load requirements of your system. Furthermore, examining the cable's installation method can guide you in selecting the right type that meets safety standards and operational efficiency. Overall, these technical specifications not only influence the performance of low voltage cables but also ensure compliance with local regulations and standards. By considering these factors, global buyers can make informed decisions that lead to enhanced reliability and long-term success in their electrical projects.

Best Practices for Selecting High-Quality Low Voltage Cable Manufacturers

When selecting high-quality low voltage cable manufacturers, buyers should prioritize a few essential criteria. First, it's crucial to assess the manufacturer's compliance with international standards, such as IEC and UL certifications. According to a report from the International Electrotechnical Commission, cables that meet these standards are less prone to faults, reducing the risk of outages and improving overall system reliability. Industrial leaders recommend that buyers verify if the manufacturer conducts rigorous testing on their products, as this can ensure better performance in various applications.

Tips: Always ask for documentation regarding testing processes and certifications before making a decision. Additionally, consider the manufacturer's reputation and industry experience. A study by Grand View Research indicates that manufacturers with over a decade of experience are more likely to provide superior products due to their established processes and knowledge.

Another factor to consider is the manufacturer's ability to supply customized cable solutions. The global low voltage cable market is evolving with increasing demand for personalized products that meet specific technical requirements. The latest data from MarketsandMarkets indicates that the customized cable segment is expected to grow at a CAGR of 5.8% through 2025. This means that selecting a manufacturer who can offer tailored solutions can add significant value to your projects.

Tips: When discussing options with potential manufacturers, inquire about their capability to meet bespoke specifications and test prototypes.

Comparative Analysis of Top Low Voltage Cable Brands in the Market

When selecting low voltage cables, it’s critical to assess the various brands available in the market to ensure the best fit for your specific needs. Not all low voltage cables are created equal; differences in material quality, insulation, and voltage rating can significantly impact performance. Leading brands such as Belden, Southwire, and Prysmian have established themselves by offering robust solutions suitable for a range of applications, from residential wiring to industrial systems. Belden, known for its durable designs, excels in providing cables that withstand harsh environments. Southwire offers a comprehensive portfolio tailored to meet stringent safety standards, while Prysmian is celebrated for its innovation and extensive testing protocols.

In a comparative analysis, Belden's focus on high-performance cables often comes at a premium price, but their reliability can justify the investment. Southwire, with its balance of quality and affordability, appeals to budget-conscious consumers without compromising safety. Meanwhile, Prysmian often leads the market in terms of technological advancements, making their cables a preferred choice for cutting-edge projects. Understanding these brand strengths enables global buyers to make informed decisions that align with their project requirements and financial considerations, ultimately unlocking excellence in their electrical installations.

Comparative Analysis of Low Voltage Cable Performance

Understanding Global Compliance Standards for Low Voltage Cables

Understanding global compliance standards for low voltage cables is essential for manufacturers and buyers alike, particularly as the demand for these cables continues to rise in various markets, including the Asia Pacific region.

As the instrumentation cable market sees substantial growth, surpassing USD 3.3 billion in 2024, it is vital for stakeholders to grasp the intricacies of regional regulations and standards. Compliance with local and international standards ensures not only the safety and reliability of electrical infrastructure but also facilitates smoother entry into competitive markets.

In the context of a growing renewable energy sector, particularly solar power in countries like India, adherence to compliance standards becomes even more critical. Low voltage cables are integral to connecting various components of power systems, and their compliance with global standards can significantly impact project timelines and efficiencies.

As industries evolve, and with technologies such as high-performance variable frequency drives becoming commonplace, understanding the compliance landscape around low voltage cables will empower stakeholders to navigate industry challenges effectively while fostering innovation and sustainable practices.