2025 Top 5 Welding Cable Products: Elevate Your Welding Game with These Must-Haves

In the dynamic world of welding, the selection of high-quality components is critical to achieving optimal performance and safety. Welding cable, as a fundamental element of the welding process, plays a pivotal role in ensuring efficient electrical conductivity and durability in various welding applications. According to the Global Welding Equipment Market report by Research and Markets, the market is projected to grow at a CAGR of 4.6% from 2021 to 2026, reflecting the increasing demand for reliable welding solutions across multiple industries, including automotive, construction, and manufacturing.

With the continuous evolution of welding technology, the importance of using the right welding cables has never been more pronounced. High-performance welding cables not only enhance the efficiency of welding operations but also significantly reduce the risks associated with electrical hazards. The American National Standards Institute (ANSI) emphasizes that utilizing cables that meet or exceed specific industry standards, such as those outlined in the National Electrical Code (NEC), is essential for ensuring safety and longevity in welding applications.

As we delve into the top five welding cable products for 2025, it becomes clear that investing in premium welding cables is a strategic move for professionals looking to elevate their welding game. These must-have products not only promise superior performance but also align with industry trends that prioritize safety, sustainability, and innovation.

Top Features to Look for in Welding Cables for Optimal Performance

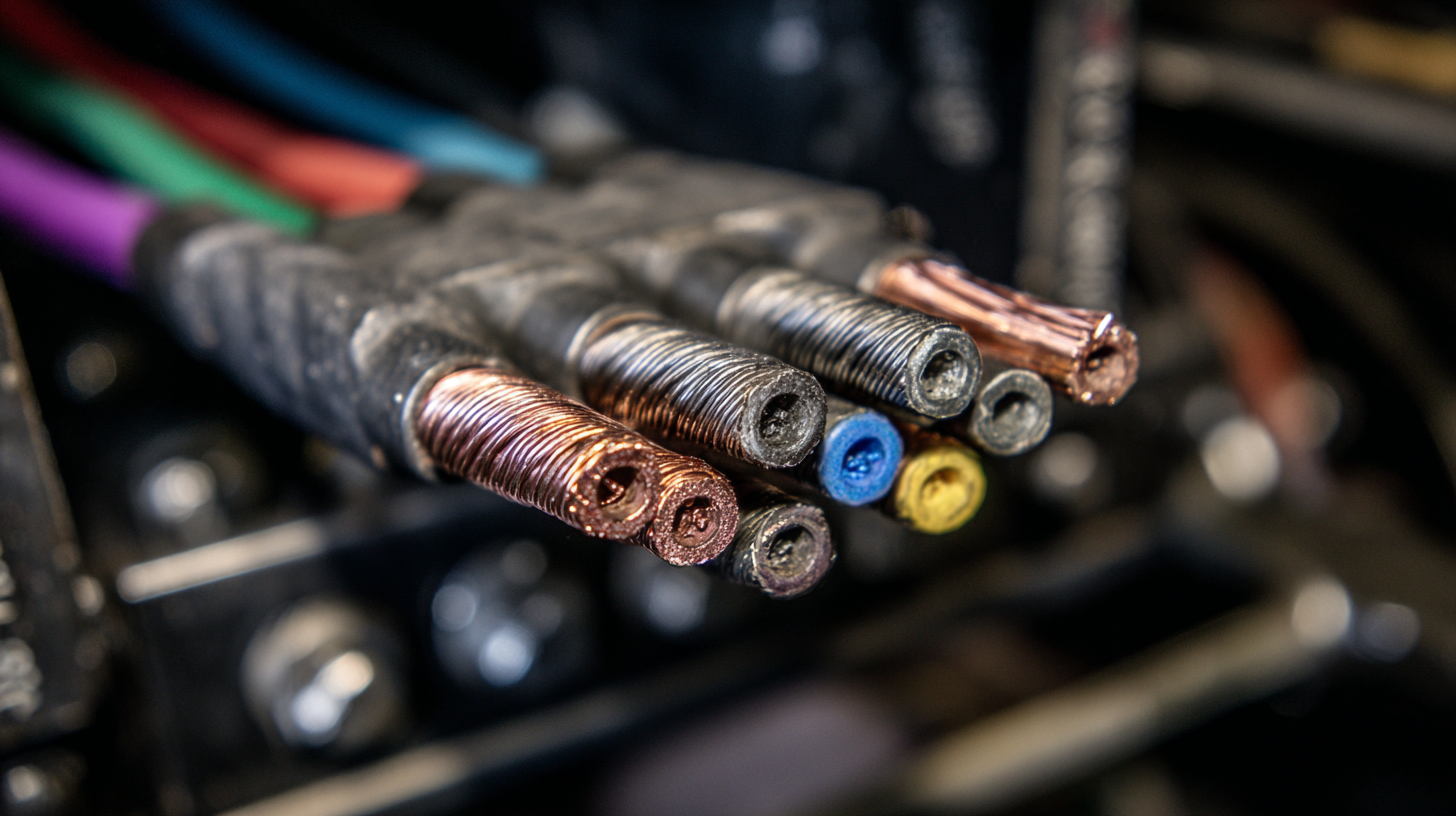

When selecting welding cables, certain key features can significantly enhance performance and safety during your welding projects. First and foremost, the flexibility of the cable is crucial. A highly flexible cable allows for easier maneuverability and reduces the risk of damage during use. Additionally, look for cables that are made with high-quality copper conductors; copper ensures better conductivity and minimizes energy loss, which can directly impact the efficiency of your welding operations.

Another essential feature is the insulation material of the cables. Opt for rubber or PVC insulation as these materials provide excellent protection against heat and abrasion. They also enhance the cable's durability, making it suitable for various work environments. Furthermore, consider the cable’s gauge; thicker cables can carry more current and are suitable for heavy-duty tasks, while lighter gauges are ideal for less demanding applications.

Tips: Always check for a cable’s amperage capacity before use to ensure it matches your welder's requirements. Regularly inspect your welding cables for signs of wear or damage and replace them promptly to maintain optimal performance. Keep your cables clean and free from debris to prolong their lifespan and reduce the risk of electrical hazards.

Comparison of Different Types of Welding Cables and Their Uses

When selecting welding cables, it's essential to understand the different types available and their applications to enhance welding efficiency and safety. Welding cables are typically classified based on the material type, such as copper, aluminum, or more specialized alloys. Copper cables are favored for their superior conductivity and strength, making them ideal for high-performance welding applications. In contrast, aluminum cables, while lighter and often more cost-effective, may not deliver the same level of conductivity and may be more suitable for less demanding tasks.

Additionally, the choice of cable can significantly impact metal transfer behavior in flux-cored arc welding. Research indicates that the presence of alkali elements can optimize the welding process by improving the transfer of metal during welding. This is crucial for achieving clean welds and reducing defects. By understanding the nuances of these materials and their specific uses, welders can elevate their performance and ensure more reliable results in their projects.

2025 Top 5 Welding Cable Products Comparison

This chart illustrates the performance ratings of the top 5 welding cable products based on various criteria such as conductivity, flexibility, and heat resistance.

Understanding the Importance of Cable Thickness in Welding Applications

When undertaking welding projects, the significance of cable thickness cannot be overstated. A thicker welding cable plays a crucial role in ensuring efficient current flow, which directly affects the quality and integrity of the weld. This is especially vital in high-amperage applications where inadequate cable thickness can lead to overheating and potential safety hazards. Choosing the right thickness not only optimizes performance but also prolongs the lifespan of the equipment.

Additionally, the thickness of welding cables influences the overall flexibility and maneuverability of the setup. Thicker cables often offer less flexibility, which may hinder movement in tight spaces. Conversely, while thinner cables may provide greater ease of use, they can compromise the welding process by causing voltage drops. Therefore, striking a balance between thickness and usability is essential for achieving optimal results in various welding applications. Understanding these factors is key to selecting the right welding cable for your specific needs, ultimately improving the effectiveness of your welding projects.

Safety Standards and Certifications for Welding Cables You Should Know

When selecting welding cables, understanding safety standards and certifications is crucial for ensuring both performance and safety in welding operations. The American National Standards Institute (ANSI) and the Underwriters Laboratories (UL) are two prominent organizations that establish safety guidelines for welding cables. Cables that comply with ANSI and UL standards not only guarantee proper insulation and conductivity but also minimize the risk of accidents caused by overheating or electrical faults.

Additionally, the National Electrical Code (NEC) provides regulations that outline the proper use of welding cables in various environments. Adhering to these standards can enhance safety in workplaces by addressing hazard prevention measures. For instance, cables labeled as "W" conform to the NEC criteria, ensuring they are suitable for use in potentially hazardous conditions. By choosing welding cables that meet these critical regulations, welders can elevate their safety protocols, ultimately leading to improved operational efficiency and peace of mind while working.

How to Properly Maintain and Store Your Welding Cables for Longevity

Proper maintenance and storage of welding cables are crucial for ensuring their longevity and optimal performance. According to industry reports, the lifespan of high-quality welding cables can exceed 10 years with proper care. Regular inspection of cables for wear and tear, such as fraying or cracks, is essential. Given that welding cables are subject to extreme conditions, it's advised to clean them regularly and to avoid bending or twisting excessively, which can lead to internal damage.

When it comes to storage, keeping welding cables in a cool, dry place is paramount. Extreme temperatures can compromise the insulation, while moisture can lead to corrosion. As indicated in recent studies, cables that are improperly stored can lose up to 30% of their efficiency over time. Utilizing storage reels or protective sheaths can help maintain their integrity, reducing the risk of damage and ensuring that they remain effective when needed. By prioritizing the maintenance and storage of welding cables, professionals can significantly improve their welding game, maximizing both safety and efficiency in their operations.

2025 Top 5 Welding Cable Products: Elevate Your Welding Game with These Must-Haves

| Cable Type | Diameter (AWG) | Rating (Amps) | Length (Feet) | Durability |

|---|---|---|---|---|

| TGGT Welding Cable | 6 AWG | 200 | 50 | Highly Durable |

| EPDM Rubber Cable | 4 AWG | 300 | 100 | Extreme Weather Resistance |

| Silicone Welding Cable | 8 AWG | 150 | 25 | Flexible & Durable |

| Flexible PVC Cable | 2 AWG | 400 | 75 | Excellent Flexibility |

| H07RN-F Cable | 10 AWG | 100 | 30 | Industrial Grade |

How to Properly Maintain and Store Your Welding Cables for Longevity

- Keep cables coiled properly to prevent kinks.

- Store cables in a dry place away from direct sunlight.

- Avoid overloading cables beyond their amp rating.

- Regularly inspect cables for any signs of wear or damage.

- Clean cables with a damp cloth after use to remove dust and debris.

Related Posts

-

Top Tips for Choosing the Best Welding Cable for Your Projects

-

7 Essential Benefits of the Best Grounding Cable for Global Buyers

-

Innovative Uses of Best Braided Ground Strap in Electrical Safety and Industry Standards

-

Top 5 Examples of the Best Automotive Wire for High-Performance Applications

-

The Ultimate Guide to Generating High Quality Welding Leads for Your Business

-

Solutions for Sourcing the Best Automotive Wire for Your Global Supply Chain