Innovative Alternatives to Traditional Automotive Wire Solutions

In the rapidly evolving automotive industry, traditional automotive wire solutions are being challenged by innovative alternatives that promise enhanced performance, reduced weight, and greater efficiency. As vehicles become more technologically advanced, the demand for superior wiring solutions has never been more critical.

This blog will explore the top strategies for implementing cutting-edge automotive wire alternatives that not only meet the stringent requirements of modern automotive design but also pave the way for future innovations. From exploring alternative materials to leveraging advanced manufacturing techniques, we will delve into how these innovative approaches can transform the way we think about automotive wiring.

Join us as we uncover the best practices and solutions that are reshaping the automotive landscape, ensuring vehicles are not only smarter but also more reliable than ever before.

Exploring the Benefits of Lightweight Wire Materials in Automotive Design

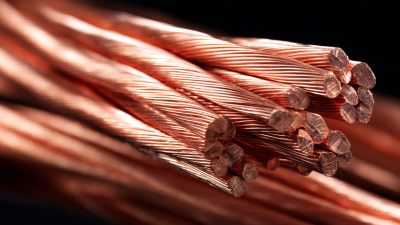

The automotive industry is undergoing a significant transformation with the adoption of lightweight wire materials, which play a crucial role in enhancing vehicle performance and efficiency. According to a recent report by the International Council on Clean Transportation, reducing vehicle weight by just 10% can improve fuel efficiency by approximately 6-8%. This statistic underscores the importance of choosing the right materials in automotive design, where wire solutions are often overlooked.

Innovative alternatives such as aluminum and composite wires are gaining traction due to their exceptional strength-to-weight ratios. For instance, a study conducted by the Automotive Materials Partnership revealed that aluminum wiring can reduce the overall wiring system weight by up to 50% compared to traditional copper alternatives. This reduction not only contributes to better fuel economy but also allows for increased design flexibility and enhanced vehicle dynamics. With the global automotive market projected to grow by 4% annually, the shift towards lightweight materials is not just a trend but a necessary evolution in automotive engineering that supports sustainability and performance.

Top Non-Conventional Insulation Techniques for Enhanced Durability

In the ever-evolving automotive industry, traditional wire insulation techniques are being challenged by innovative alternatives aimed at enhancing durability and performance. As the demand for lightweight and robust materials grows, especially in the face of increasing safety regulations and the quest for fuel efficiency, automotive manufacturers are looking beyond conventional solutions. Non-conventional insulation techniques, such as the use of advanced technical textiles, are becoming prominent. These materials not only offer superior insulation properties but also exhibit remarkable resistance to abrasion, temperature variations, and environmental factors that traditional insulators struggle to withstand.

The technical textiles market is on a significant growth trajectory, projected to reach a remarkable $205.4 billion by 2024, with a robust compound annual growth rate exceeding 4.9% expected from 2025 to 2034. This surge is largely driven by burgeoning demand for specialty materials in various sectors, including medical disposable products and personal protective equipment. As automotive applications become increasingly intertwined with these advanced textile solutions, the integration of such materials in vehicle wiring and insulation will likely play a key role in shaping the future of automotive design, rendering vehicles safer and more efficient.

Evaluating Flexible Wiring Solutions for Modern Automotive Applications

As the automotive industry evolves, the demand for flexible wiring solutions grows significantly. Modern vehicles are becoming increasingly sophisticated, featuring a range of electronic components that require efficient and lightweight wiring systems. Traditional automotive wires can be cumbersome, often contributing to weight and space issues within the vehicle. In contrast, innovative alternatives such as flat ribbon cables and flexible printed circuits present a more adaptable solution, facilitating easier routing and installation in confined spaces.

**Tips:** When considering flexible wiring solutions, prioritize materials that offer durability and resistance to harsh conditions, such as high temperatures and moisture. Additionally, keep in mind the specific electrical requirements of your applications to ensure compatibility and optimal performance.

Implementing these advanced wiring options not only enhances the functionality of automotive systems but also streamlines the assembly process. By integrating flexible wiring solutions, manufacturers can reduce production costs while improving the overall design and performance of their vehicles.

**Tips:** Regularly evaluate the performance of wiring solutions during testing phases to identify potential issues early. Collaboration with suppliers who specialize in flexible wiring can lead to innovative designs tailored specifically for your automotive needs.

Innovative Alternatives to Traditional Automotive Wire Solutions - Evaluating Flexible Wiring Solutions for Modern Automotive Applications

| Solution Type | Material | Flexibility Rating | Temperature Resistance (°C) | Applications |

|---|---|---|---|---|

| Flat Wire | Copper | High | -40 to 125 | Battery Connectors, Electronics |

| Flexible Ribbon Cable | Copper Alloy | Very High | -40 to 150 | LED Lighting, Sensors |

| Polymer Coated Wire | Aluminum | Moderate | -30 to 120 | Chassis Wiring |

| Bundled Cables | Copper | High | -40 to 130 | Main Harness, Control Units |

| Heat Shrink Tubing | Polyolefin | Moderate | -55 to 125 | Insulation for Connections |

Sustainable Alternatives: Eco-Friendly Materials in Automotive Wiring Systems

The automotive industry is experiencing a significant shift towards sustainability, particularly in the realm of wiring systems. Traditional materials used in automotive wiring, such as copper and PVC, are facing scrutiny due to their environmental impact. According to a report by the International Energy Agency (IEA), the automotive sector is responsible for approximately 22% of global CO₂ emissions, prompting manufacturers to explore more eco-friendly alternatives. Biomaterials, such as bioplastics derived from renewable resources, are emerging as viable options, offering similar conductivity and insulation properties while reducing reliance on fossil fuels.

Recent advancements in sustainable materials have led to the development of wire systems that use recycled metals and biodegradable polymers. For instance, a study published by the Society of Automotive Engineers (SAE) highlighted that replacing conventional wiring with composite materials made from natural fibers could potentially reduce vehicle weight by up to 15%. This not only lowers manufacturing emissions but also enhances fuel efficiency, contributing to a greener automotive future. As environmental regulations tighten and consumer demand for green technologies grows, eco-friendly wiring solutions are poised to play a crucial role in the evolution of automotive design and engineering.

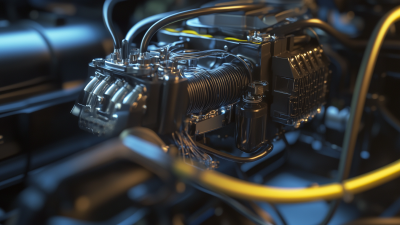

Cutting-Edge Technologies Transforming Automotive Wiring Solutions

The automotive industry is witnessing a significant shift as cutting-edge technologies redefine traditional wiring solutions. With the growing complexity of electric vehicles (EVs), the demand for innovative alternatives to conventional automotive wiring has surged. Industry reports indicate that advanced materials and lightweight wiring systems can reduce overall vehicle weight by as much as 15%, directly enhancing energy efficiency and performance. The integration of AI-powered applications is also paving the way for smarter wiring solutions, allowing for real-time data exchange and diagnostics that improve overall vehicle safety and reliability.

In addition, collaborations between major players are rapidly transforming automotive production. Recent developments in digital production platforms are streamlining the manufacturing processes, effectively reducing production time and costs. By harnessing big data and IoT technologies, manufacturers can optimize wiring layouts and configurations, leading to more efficient designs. As cities focus on mobility technologies to meet the demands of modern transport, the evolution of automotive wiring solutions is not only accelerating innovation within the industry but also contributing to a sustainable future for urban transport systems. These advancements are reshaping how vehicles connect and communicate, ultimately enhancing the driving experience.

Related Posts

-

Top 5 Examples of the Best Automotive Wire for High-Performance Applications

-

Solutions for Sourcing the Best Automotive Wire for Your Global Supply Chain

-

Maximize Value with Best Copper Wire After Sales Service Tips to Reduce Repair Costs

-

Top Tips for Choosing the Best Welding Cable for Your Projects

-

Unlocking Excellence: In-Depth Technical Specifications of the Best Low Voltage Cable for Global Buyers

-

Innovative Uses of Best Braided Ground Strap in Electrical Safety and Industry Standards