10 Essential Facts About Direct Burial Wire for Your Next Project

When planning your next electrical project, understanding the intricacies of Direct Burial Wire is crucial. According to the National Electrical Code (NEC), wiring systems designed for direct burial can significantly enhance safety and efficiency, particularly in outdoor applications. A recent study by the National Electrical Manufacturers Association (NEMA) indicates that improper wiring choices are a leading cause of electrical failures in residential installations, underscoring the importance of using the right materials. Direct Burial Wire is specifically engineered to withstand harsh environmental conditions, making it an optimal choice for direct applications underground. With data showing that nearly 30% of electrical installations could benefit from improved wire selection, knowing the essential facts about Direct Burial Wire can not only elevate the quality of your work but also ensure compliance with industry standards. By focusing on the key aspects of this type of wire, you'll be better equipped to make informed decisions that enhance the longevity and safety of your electrical systems.

Understanding Direct Burial Wire: What It Is and When to Use It

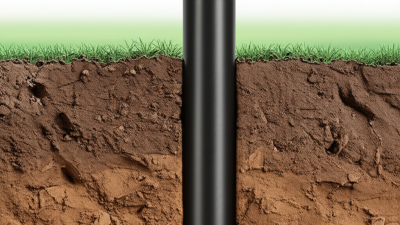

Direct burial wire is an essential component for various electrical projects, especially when considering installation below ground. This type of wire is specifically designed to withstand the rigors of underground environments, including moisture and soil acidity, which can compromise standard wiring. While the choice between overhead and underground wiring continues to spark debates, more cities, such as New Delhi and Panaji, are opting for underground systems. This transition not only enhances safety but also improves the aesthetics of urban landscapes.

In recent discussions surrounding electrical infrastructure, the importance of direct burial wire has been highlighted. With significant projects underway, there is a growing recognition of the benefits of underground cable installations. For instance, researchers are utilizing unused fiber-optic cables to create extensive maps and understand seismic activity better. Furthermore, with increasing government initiatives aimed at adopting underground wiring, direct burial wire is likely to play a crucial role in future projects, ensuring reliability and safety while addressing the aesthetic and practical challenges of overhead connections.

Key Benefits of Direct Burial Wire Over Traditional Wiring Solutions

When it comes to electrical installations, choosing the right type of wiring can significantly impact both safety and efficiency. Direct burial wire stands out as a superior option compared to traditional wiring solutions. One of the key benefits of direct burial wire is its robust construction, designed specifically to withstand underground conditions. This type of wire is typically encased in a waterproof and UV-resistant jacket, ensuring longevity and reliability while reducing the risk of damage from moisture and soil acidity.

Another critical advantage is the simplicity of installation. Direct burial wire eliminates the need for conduit in many cases, allowing for a more straightforward, faster, and often cost-effective installation process. This advantage is particularly appealing for outdoor projects, where digging trenches for conduit can be labor-intensive and time-consuming. Moreover, once installed, direct burial wire requires minimal maintenance, providing peace of mind for homeowners and contractors alike. Overall, the durability and ease of use make direct burial wire an excellent choice for various applications, from landscape lighting to powering outdoor structures.

Safety Considerations: Best Practices for Installing Direct Burial Wire

When installing direct burial wire, safety should always be a top priority. According to the National Electrical Code (NEC), proper depth for burying direct burial wire is crucial to prevent damage from environmental elements and ensure optimal performance. Typically, non-metallic underground cable should be buried at least 24 inches deep, while underground feeder (UF) cable requires a minimum depth of 18 inches. Adhering to these standards reduces the risk of accidental digs, which can lead to costly repairs and potential safety hazards.

In addition to depth requirements, using the correct type of cable for your specific application is essential. The Underwriters Laboratories (UL) reports that direct burial wires are constructed with moisture-resistant materials to prevent corrosion and ensure longevity when buried in the ground. It is also recommended to use warning tape above the buried wire to prevent future disturbances. Following these best practices not only enhances safety for installers and homeowners alike but also ensures compliance with local building codes, ultimately contributing to a successful project.

Choosing the Right Gauge and Type of Direct Burial Wire for Your Project

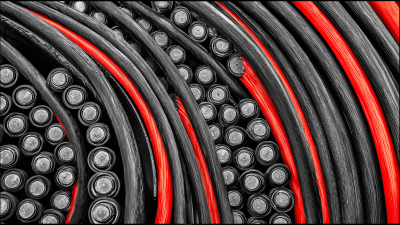

When it comes to choosing the right gauge and type of direct burial wire for your project, understanding the specifics can make a significant difference in performance and safety. Direct burial wire is designed for underground installation, resisting moisture and corrosion. For most residential applications, a 12-gauge wire is suitable, providing a good balance between capacity and ease of handling. However, for longer runs or heavier loads, you may want to consider a thicker gauge, such as 10 or even 8-gauge, to minimize voltage drop.

Tip: Always check local electrical codes and regulations before purchasing wire. They often specify the minimum wire gauge for different applications, ensuring both safety and efficiency.

Another important aspect to consider is the type of insulation. THHN (Thermoplastic High Heat-resistant Nylon-coated) wire is commonly used for indoor applications but is not ideal for direct burial. Instead, opt for UF (Underground Feeder) wire, which is specifically designed to withstand soil conditions without additional protection.

Tip: When planning your installation, ensure proper spacing and depth to prevent physical damage and allow for adequate drainage. Remember, proper installation today can save you a lot of trouble in the future.

Wire Gauge Comparison for Direct Burial Projects

Maintenance Tips to Ensure Longevity of Direct Burial Wire Installations

When installing direct burial wire for outdoor projects, ensuring its longevity is crucial. Proper maintenance plays a key role in protecting your investment and maximizing its lifespan. One of the essential tips is to regularly inspect the wiring and connections for any signs of wear or damage. Look for frays, breaks, or corrosion that could compromise the wire's integrity. Keeping the area around the installation clear of debris and moisture will help prevent unnecessary strain on the wire and reduce the risk of underground issues.

Additionally, consider using protective conduits to shield the wire from environmental factors such as heavy rains or very cold temperatures. This added layer of protection can significantly extend the life of your direct burial wire. Regularly checking the performance of the systems connected to the wire will also help identify any potential problems early on, allowing for timely repairs before they escalate. Maintenance may seem like a minor aspect, but it is vital for maintaining the functionality and safety of your direct burial wire installations.

Related Posts

-

Unlocking Efficiency: The Advantages of Direct Burial Cable for Outdoor Applications

-

Empowering Your Future with Best Power Cord Trends for 2025 and How to Choose the Right One

-

Top 5 Examples of the Best Automotive Wire for High-Performance Applications

-

Solutions for Sourcing the Best Automotive Wire for Your Global Supply Chain

-

China's Excellence in Best Low Voltage Cable Manufacturing Leading Export Powerhouse

-

The Complete Guide to Choosing the Best Grounding Wire for Your Needs