Unlocking Efficiency: The Advantages of Direct Burial Cable for Outdoor Applications

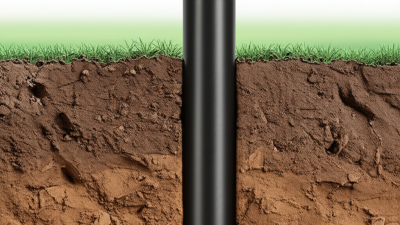

In today's fast-paced world, the need for reliable and efficient outdoor electrical installations has never been more critical, particularly as more industries embrace advanced technologies. One solution that stands out in this realm is the use of Direct Burial Cable. This specialized type of cable is designed for underground installations, offering exceptional durability and resistance to environmental factors. Unlike traditional wiring methods that require extensive conduit setups, Direct Burial Cable simplifies the installation process, cutting down on time and labor costs.

Its robust construction enables it to withstand harsh conditions, making it an ideal choice for a variety of outdoor applications, from landscaping lighting to telecommunications. In this blog, we will explore the many advantages of Direct Burial Cable, providing valuable insights and examples that demonstrate its efficiency and effectiveness in modern electrical systems.

Understanding Direct Burial Cable: What You Need to Know

Direct burial cable is specifically designed for underground installation, making it an ideal choice for outdoor applications. This type of cable is typically constructed with robust materials that can withstand exposure to moisture, soil, and varying temperatures. According to a report from the International Electrotechnical Commission, direct burial cables can last up to 30 years or more when properly installed, significantly reducing the need for replacements and maintenance over time.

One of the key advantages of direct burial cables is their ease of installation. Unlike traditional cables, which may require conduits and additional protective mechanisms, these cables can be directly placed in the ground, streamlining the installation process. The National Electrical Manufacturers Association (NEMA) notes that this efficiency can cut installation times by as much as 25%. Additionally, direct burial cables minimize the risk of damage from environmental factors, providing a more reliable solution for powering outdoor lighting, irrigation systems, and other outdoor electrical projects.

Key Benefits of Using Direct Burial Cable for Outdoor Applications

Direct burial cable has become an increasingly preferred choice for outdoor applications due to its numerous advantages. One primary benefit is its robust construction, designed to withstand harsh environmental conditions. Unlike traditional wire types, direct burial cables are engineered with a protective coating that resists moisture and physical damage, enabling them to function reliably underground. This durability translates into fewer maintenance issues and an extended lifespan, leading to cost savings over time—a crucial factor in both residential and commercial installations.

Moreover, the efficiency of direct burial cable extends beyond its physical attributes. Its installation process is typically more straightforward, requiring less labor and shorter project timelines. Data suggests that the implementation of direct burial cables can reduce installation time by up to 30%, promoting prompt project completion, especially in urban development. As industries shift towards smart technologies, the demand for efficient and resilient communication lines is rising. By using direct burial cables, businesses can ensure stable connectivity for IoT applications, enhancing operational efficiency in diverse sectors, from agriculture to environmental monitoring. This integration aligns with the growing emphasis on sustainable practices and innovation, showcasing how direct burial cables can support modern infrastructure needs while providing long-lasting performance.

Installation Best Practices for Direct Burial Cable

When it comes to outdoor applications, using direct burial cable can significantly enhance installation efficiency and reliability. As outlined in the National Electrical Code (NEC), proper adherence to regulations is paramount for outdoor wiring. The NEC emphasizes specific requirements that ensure safety and efficiency, such as suitable burial depths and protective conduits for different climates and soil conditions. This not only safeguards the integrity of the cables but also reduces the risk of utility service interruptions that could arise from damage or exposure.

**Tips for Best Practices:**

1. **Choose the Right Cable Type:** Ensure the direct burial cable is rated for outdoor use and has the necessary insulation to withstand moisture and temperature variations.

2. **Follow NEC Guidelines:** Be aware of the NEC regulations regarding burial depth, typically at least 24 inches for direct burial, to avoid unforeseen hazards during digging activities.

3. **Utilize Advanced Distribution Systems:** Consider advancements in underground distribution systems, which can help in planning and implementing durable, effective wiring solutions.

The implementation of these best practices can not only streamline installations but also bolster the shift toward more sustainable energy systems, as seen in the latest infrastructure developments for underground electricity cables in various locales. By focusing on these guidelines, utility providers can pave the way for safer and more efficient outdoor electrical installations.

Common Misconceptions About Direct Burial Cable

When it comes to outdoor wiring solutions, direct burial cable (DBC) often faces misconceptions that hinder its widespread adoption. Many believe that DBC is less reliable than traditional overhead wiring systems. However, industry data shows that direct burial cables are designed to resist moisture, temperature fluctuations, and physical stress, making them ideal for underground installations. According to a report by the National Electrical Manufacturers Association (NEMA), DBC can offer an extended lifespan of over 30 years with proper installation, highlighting its durability compared to conventional cables.

Another common misconception is that the installation of direct burial cables is more complicated and costly. In reality, while the initial investment might be comparable to other options, the long-term savings in maintenance and reduced susceptibility to environmental damage make DBC a more economical choice. A study by the Electric Power Research Institute (EPRI) revealed that utilities could save up to 20% annually on maintenance costs by opting for direct burial solutions. This efficiency not only applies to cost but also to the ease of installation, as these cables do not require the same level of infrastructure support as overhead lines, further enhancing their suitability for outdoor applications.

Maintenance Tips to Ensure Longevity of Direct Burial Systems

When implementing direct burial cable systems for outdoor applications, ensuring their longevity is paramount. Frequent maintenance can significantly enhance the performance and lifespan of these cables. According to a report by the National Electrical Manufacturers Association (NEMA), proper maintenance can extend the life of direct burial cables by up to 30%. This emphasizes the need for vigilance and proactive measures.

Tip 1: Regularly inspect the installation site for signs of physical damage or exposure to environmental elements. Look for soil erosion or tree root encroachment, which may compromise the cable’s integrity. Keeping vegetation trimmed around the cable path can prevent potential abrasion and damage.

Tip 2: Conduct periodic tests to assess cable performance. Utilizing tools like insulation resistance testers can help detect issues early. The Institute of Electrical and Electronics Engineers (IEEE) suggests performing these tests annually to ensure optimal functionality and mitigate risks of downtime.

By adhering to these maintenance practices, users can unlock the full potential of direct burial cable systems, ensuring they remain reliable and efficient for years to come.