What is a Damper Actuator and How Does it Work?

In the modern world of HVAC systems, the Damper Actuator plays a crucial role. It regulates airflow in ventilation and exhaust systems. Experts like Dr. Emily Carter, an authority in HVAC technology, emphasize its importance. She states, "A damper actuator ensures optimal airflow management and energy efficiency."

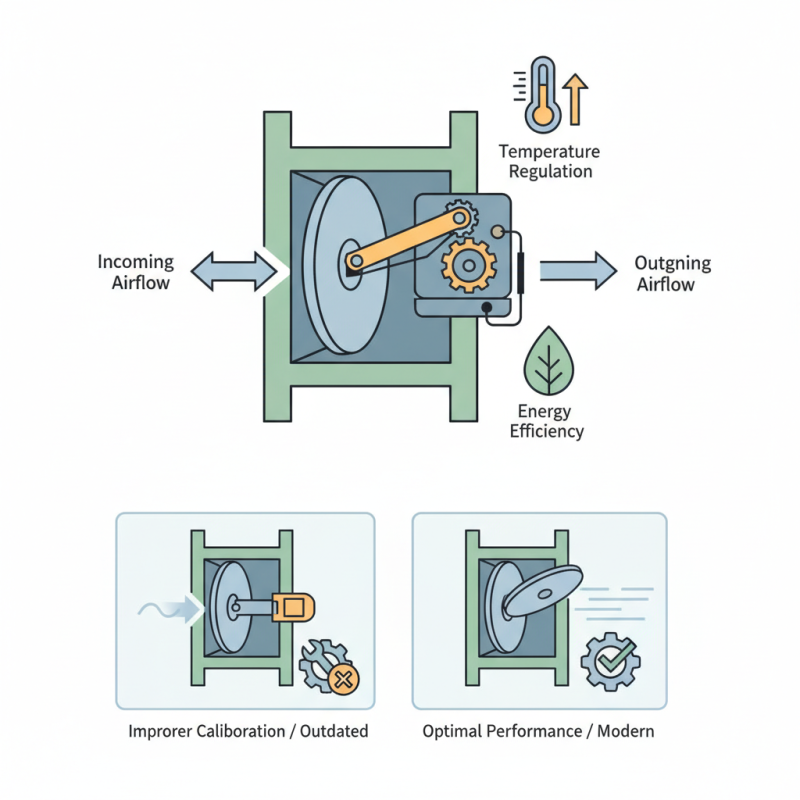

Understanding how a damper actuator works is essential for HVAC specialists. These devices automatically adjust dampers based on control signals. However, not all systems use them effectively. Some installations suffer from improper calibration or outdated components. This can lead to insufficient airflow and energy waste.

As designers face increasing demands for efficiency, embracing damper actuators becomes vital. Outdated methods may hinder progress. The challenge lies in adapting to new technology while ensuring reliable performance. Meeting these expectations often prompts scrutiny of existing systems and practices. Evaluating the effectiveness of damper actuators should remain a priority.

Definition of a Damper Actuator and Its Purpose

A damper actuator is a crucial component in HVAC systems. Its main purpose is to control airflow. This device regulates the position of dampers. These dampers are found in air ducts. They help in managing temperature and air balance.

The damper actuator can be electric, pneumatic, or hydraulic. Each type has its own benefits. Electric actuators are common due to their precision. They can adjust quickly and accurately. On the other hand, pneumatic actuators operate using air pressure. They can be powerful but may need more maintenance.

Tip: Regularly check your damper actuator for any signs of wear. Keeping it in good condition will ensure optimal airflow and efficiency.

These actuators sometimes face issues. They may stick or fail to respond. If your system isn’t working well, inspect the actuator. It could be a simple fix that makes a big difference.

Tip: Record any changes in performance. This can help identify patterns over time. Knowing when problems occur assists in troubleshooting.

Types of Damper Actuators in HVAC Systems

Damper actuators play a vital role in HVAC systems. They control the airflow by opening and closing dampers. This ensures proper ventilation and maintains desired temperatures. There are various types of damper actuators, each with unique features.

Electric damper actuators are common in many systems. They provide precise control with quick response times. According to industry reports, nearly 75% of HVAC systems now use electric actuators.

Pneumatic actuators are another option, using air pressure to function. They are simple and reliable but may lag in performance compared to electric ones. Some systems also employ hybrid actuators, combining both mechanisms.

Choosing the right actuator is crucial for efficiency. Some buildings may face integration issues with existing systems. Not all actuators work seamlessly with both old and new technologies. This inconsistency can lead to suboptimal energy use. Hence, analyzing specific requirements is essential.

Effective airflow management can reduce energy costs, promoting sustainability. One study indicates that proper actuator selection can enhance system efficiency by up to 30%.

Mechanisms of How Damper Actuators Operate

Damper actuators play a critical role in various HVAC systems. These devices control the flow of air through ductwork by adjusting dampers. They can be electric, pneumatic, or hydraulic. Each type has its own mechanisms. Electric actuators often utilize a motor to turn a shaft connected to the damper. Pneumatic actuators rely on air pressure, while hydraulic actuators use fluid power.

Understanding how these actuators work is key. For instance, electric models typically react to signals from a thermostat or building management system. This allows precise control over airflow. Data from industry studies suggest that efficient damper operation can improve energy savings by up to 30%. It also optimizes indoor air quality. However, not every system achieves these benefits equally.

Tip: Regular maintenance is crucial for damper actuators. Dust and debris can impede performance. Some systems may require recalibration often. Address malfunctions promptly to maintain efficiency. A neglected actuator can lead to imbalanced airflow, causing discomfort and additional costs. Always consult operational guidelines for your specific setup.

Inconsistent performance needs attention. Think critically about your system’s needs and seek improvements where possible.

Applications of Damper Actuators in Various Industries

Damper actuators play a crucial role in multiple industries. They control airflow in various systems. Understanding their applications can help optimize operations. In HVAC systems, these actuators regulate heating and cooling. Proper function leads to energy efficiency, which is invaluable in building management.

In the automotive industry, damper actuators help regulate cabin temperature. They manage airflow to enhance comfort. If they fail, it can lead to uneven temperatures. This might cause frustration for passengers. Regular checks can prevent such issues. Outdated models may require upgrades to improve performance.

Tip: Consider investing in modern damper actuators. They can enhance system reliability. Perform routine maintenance to ensure peak performance. Regular assessments can identify issues before they escalate. This proactive approach saves time and resources.

Benefits of Using Damper Actuators in Airflow Regulation

Damper actuators play a crucial role in managing airflow within HVAC systems. They help regulate temperature and maintain comfort levels. By adjusting airflows, these devices can enhance energy efficiency, ensuring that energy isn’t wasted. When properly calibrated, they can lead to significant energy savings.

Using damper actuators improves indoor air quality. They help balance fresh air intake with recycled air. This balance reduces the risk of mold and allergens. A well-functioning system can contribute to a healthier living environment.

**Tip:** Regular maintenance of damper actuators is important. Dust and debris can hinder their performance.

In situations where airflow is inconsistent, consider re-evaluating the actuator placement. Improper positioning can lead to ineffective airflow control. It’s important to be mindful of their settings and ensure they respond accurately to changes in demand.

**Tip:** Use sensors to monitor performance. This can help fine-tune adjustments and improve overall efficiency.

Damper Actuator Performance Comparison

This chart compares the performance of different types of damper actuators based on factors such as response time, power consumption, and maximum torque. These metrics illustrate the advantages of using damper actuators for effective airflow regulation in HVAC systems.