The Ultimate Guide to Choosing Battery Cable Connectors for Your Global Sourcing Needs

In today's rapidly evolving global market, selecting the right Battery Cable Connectors is crucial for ensuring the efficiency and reliability of your electrical systems. Whether you are sourcing components for automotive applications, renewable energy solutions, or industrial machinery, understanding the myriad of options available is essential. Battery Cable Connectors serve as the critical link between power sources and devices, and choosing the right type can significantly impact performance, durability, and safety. This ultimate guide will navigate you through the essential factors to consider—such as materials, compatibility, and environmental resistance—while also highlighting the top connector types suited for various applications. By the end of this guide, you will be well-equipped to make informed decisions that align with your global sourcing needs.

Understanding Battery Cable Connector Types and Their Applications

When selecting

battery cable connectors,

it’s essential to understand the various types available and their specific applications.

There are primarily two categories of battery cable connectors:

crimp connectors

and

solder connectors.

Crimp connectors are favored for their ease of use and reliability, requiring only a simple crimping tool to secure the connection.

They are widely used in automotive and industrial applications where vibration and movement may cause other connection types to fail.

On the other hand, solder connectors offer superior conductivity and are ideal in scenarios where performance is crucial.

These connectors are commonly used in high-performance electronic devices and marine applications, where a robust, long-lasting connection is necessary.

Additionally, when considering the gauge of the wire and the current it will carry, it’s vital to ensure the chosen connectors can handle the specific load requirements.

Understanding these connector types and their appropriate applications can significantly streamline the process of global sourcing,

ensuring that you select the right components for your unique needs.

Key Factors to Consider When Selecting Battery Cable Connectors

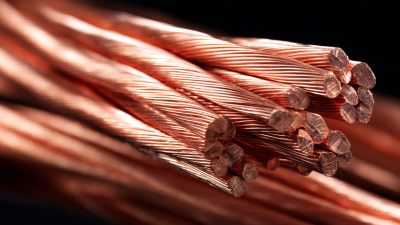

Choosing the right battery cable connectors is crucial for ensuring efficient power transfer and long-term reliability, especially for global sourcing needs. One of the key factors to consider is the material of the connectors. Copper connectors, for instance, offer excellent conductivity and durability, while aluminum connectors are lighter and often more cost-effective. Assessing the material's corrosion resistance is also essential, particularly for applications in harsh environments.

Another significant factor is the connector's size and compatibility with existing systems. It is vital to match the connector to the cable gauge and ensure it can handle the required current load without overheating. Additionally, consider the connector type—whether it's a ring terminal, spade connector, or plug type—as each has its specific applications. Lastly, pay attention to certifications and standards compliance, such as UL or ISO, to guarantee quality and safety, especially when sourcing connectors from different regions.

Analyzing the Industry Standards for Battery Cable Connectors

When choosing battery cable connectors for your global sourcing needs, understanding industry standards is paramount. Battery cable connectors serve as critical components in various applications, enabling efficient power transmission and ensuring safety. Standards such as SAE, IEC, and UL play a crucial role in guiding manufacturers and consumers in selecting appropriate connectors. These regulations dictate specifications concerning material durability, electrical conductivity, and temperature resistance, ensuring that the connectors meet performance expectations in diverse environments.

Moreover, compliance with industry standards helps mitigate risks associated with subpar connections, such as overheating, short circuits, or even battery failures. By adhering to established guidelines, companies can enhance the reliability of their products and build consumer trust. It’s essential to evaluate potential suppliers based on their commitment to industry certifications, which can indicate their adherence to rigorous testing and quality control measures. As global markets evolve, staying informed about these standards can empower businesses to make safer, more informed choices regarding battery cable connectors in their sourcing practices.

The Ultimate Guide to Choosing Battery Cable Connectors for Your Global Sourcing Needs - Analyzing the Industry Standards for Battery Cable Connectors

| Connector Type | Material | Current Rating (Amps) | Voltage Rating (Volts) | Temperature Range (°C) | Industry Standard Compliance |

|---|---|---|---|---|---|

| Ring Terminal | Copper | 50 | 600 | -40 to 120 | UL, CSA |

| Spade Connector | Brass | 30 | 300 | -20 to 85 | ISO, RoHS |

| Butt Connector | Aluminum | 40 | 600 | -40 to 125 | ANSI, RoHS |

| Female Connector | Tin-plated Copper | 70 | 500 | -40 to 150 | SAE, UL |

Evaluating Material Choices for Optimal Performance and Durability

When selecting battery cable connectors for global sourcing, choosing the right materials is crucial for achieving optimal performance and durability. According to a report by Research and Markets, the global battery connectors market is expected to grow at a CAGR of 6.5% from 2021 to 2028, primarily driven by advancements in material science and manufacturing technologies. The type of material used in battery connectors directly affects their electrical conductivity, resistance to corrosion, and thermal performance, which in turn influences the overall efficiency of electrical systems.

When selecting battery cable connectors for global sourcing, choosing the right materials is crucial for achieving optimal performance and durability. According to a report by Research and Markets, the global battery connectors market is expected to grow at a CAGR of 6.5% from 2021 to 2028, primarily driven by advancements in material science and manufacturing technologies. The type of material used in battery connectors directly affects their electrical conductivity, resistance to corrosion, and thermal performance, which in turn influences the overall efficiency of electrical systems.

Copper and aluminum are the two most commonly used materials for battery cable connectors. Copper, with its superior conductivity, is often favored for high-performance applications, offering a conductivity of around 59.6 S/m. However, aluminum connectors, which have become increasingly popular due to cost-effectiveness and weight reduction, offer significant advancements in alloy formulations that enhance their conductivity and reliability. The Automotive Industry Action Group (AIAG) highlights the importance of proper material selection to minimize failures in electrical systems, indicating that inappropriate material choice can lead to increased resistance and potential overheating. Thus, evaluating these material characteristics is essential to ensure longevity and reliability in battery applications.

Cost Comparison: The Financial Impact of Different Connector Options

When sourcing battery cable connectors, understanding the cost differences between various options is crucial for making informed decisions. The financial impact can vary significantly based on the materials used, connector design, and manufacturer. For instance, while premium connectors may have a higher initial cost, they often offer superior durability and conductivity, leading to long-term savings through reduced maintenance and replacement costs.

Tip: Before making a purchase, conduct a thorough analysis of the total cost of ownership of each connector option. This includes considering factors such as installation costs, potential failure rates, and the lifespan of the connectors. Select a connector that balances quality with affordability to ensure reliability without overspending.

Additionally, it's beneficial to compare suppliers to uncover any hidden fees or shipping costs that may affect the final price. Some manufacturers may offer bulk discounts or loyalty programs that can significantly lower your overall expenditure.

Tip: Don’t hesitate to request detailed quotes from multiple suppliers and negotiate terms to achieve the best possible pricing. This approach not only helps in securing a competitive deal but also provides insight into the market rates for high-quality battery cable connectors.

Related Posts

-

Innovative Uses of Best Braided Ground Strap in Electrical Safety and Industry Standards

-

The Complete Guide to Choosing the Best Grounding Wire for Your Needs

-

Global Reach of Chinese Technology through Best Power Extension Quality Solutions

-

Innovative Alternatives to Traditional Automotive Wire Solutions

-

Maximize Value with Best Copper Wire After Sales Service Tips to Reduce Repair Costs

-

Top 5 Examples of the Best Automotive Wire for High-Performance Applications