Top 5 Examples of the Best Automotive Wire for High-Performance Applications

In the rapidly evolving automotive industry, the demand for high-performance components has never been greater, particularly in the realm of automotive wire. According to a recent report by MarketsandMarkets, the global automotive wire market is projected to reach USD 30.07 billion by 2025, growing at a CAGR of 6.3% from 2020. This surge is driven by advancements in electric vehicles and the increasing integration of sophisticated technology in modern automobiles, necessitating reliable and efficient wiring solutions. Automotive wire is crucial in ensuring the durability and efficiency of electrical systems, which are pivotal for performance-oriented applications. As manufacturers aim for higher standards to meet both consumer expectations and regulatory requirements, understanding the nuances of automotive wire selection will not only enhance vehicle performance but also contribute to overall safety and reliability. In this blog, we will explore the top five examples of the best automotive wire designed specifically for high-performance applications, emphasizing their importance in the future of automotive innovation.

Top 5 Characteristics of High-Performance Automotive Wire for Aftermarket Applications

When it comes to aftermarket automotive applications, the right wire can make all the difference in performance and durability. High-performance automotive wire must exhibit distinct characteristics to withstand the rigors of demanding environments. One of the top traits is heat resistance; wires that are capable of withstanding temperatures up to 200°C (392°F) are essential, as reported by the Society of Automotive Engineers (SAE). This characteristic ensures they can function efficiently even in high-temperature scenarios, preventing failure and enhancing reliability.

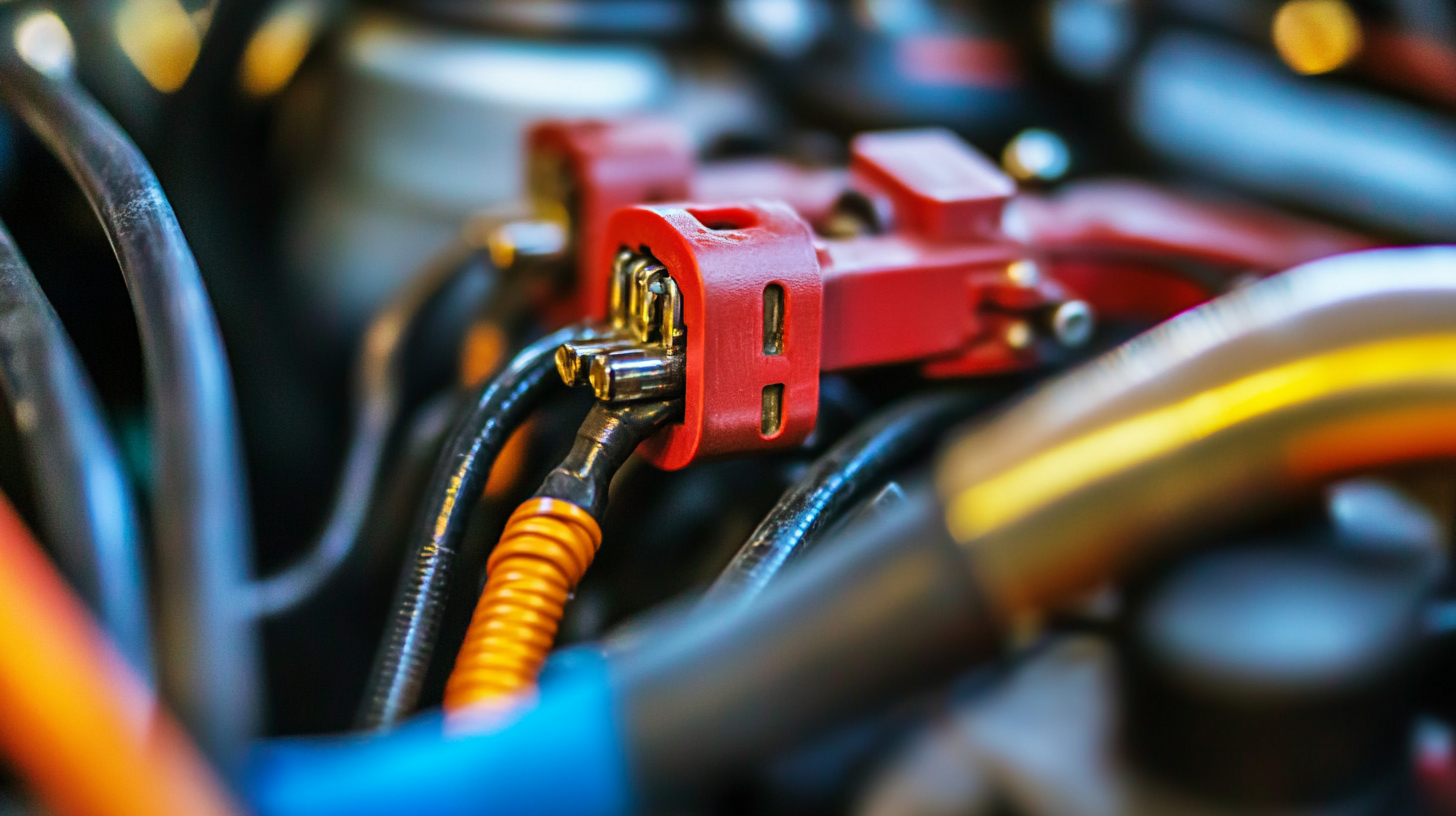

Another crucial characteristic is flexibility. High-performance wires should be able to bend and twist while maintaining integrity, which allows for easier installation and routing within tight spaces. A recent study by the International Journal of Automotive Technology revealed that flexible wires improve installation compatibility by 30%. Additionally, these wires should feature a robust insulation material, such as cross-linked polyethylene (XLPE), to prevent abrasion and chemical damage, thus increasing their lifespan.

**Tips:** When selecting automotive wire, always consider the specific application environment. Utilizing wires that comply with standards such as SAE J1128 can provide an additional layer of assurance in terms of performance and safety. Moreover, investing in high-quality connectors can significantly enhance conductivity and minimize energy loss, further optimizing your vehicle's performance.

Top 5 Characteristics of High-Performance Automotive Wire for Aftermarket Applications

This chart illustrates the key performance characteristics of high-performance automotive wire that are essential for aftermarket applications. The scores reflect the importance of each characteristic in terms of efficiency and reliability.

Cost Analysis of High-Performance Automotive Wiring: Maintenance and Repair Implications

High-performance automotive wiring is essential for maximizing the efficiency and reliability of modern vehicles. However, the cost implications associated with these premium materials cannot be overlooked. Investing in high-quality wires may lead to higher initial expenses; yet, the long-term maintenance and repair benefits can justify this choice. High-performance wiring tends to have improved durability, reduced resistance, and better heat tolerance, resulting in fewer breakdowns and lower repair costs over time.

Moreover, utilizing advanced wiring solutions can significantly enhance the overall performance of high-powered automotive systems. While the upfront costs might seem steep, the extended lifespan and reduced failure rates contribute to lower maintenance frequency and expenses. This strategic approach not only optimizes vehicle performance but also incorporates a proactive maintenance mindset, where potential issues are mitigated before they escalate into costly repairs. As such, embracing high-performance automotive wiring emerges as a wise choice for both performance enthusiasts and those mindful of long-term cost efficiency.

Real-World Performance: Case Studies of Automotive Wire in Racing Environments

In the world of high-performance racing, the importance of using the right automotive wire cannot be overstated. One striking case study revolves around the use of lightweight, high-temperature silicone wire in Formula 1 vehicles. This type of wire not only reduces the overall weight of the car, contributing to better acceleration, but also withstands extreme temperatures generated during intense racing conditions. Teams have reported significantly improved reliability in their electrical systems, which is crucial when every millisecond counts on the track.

Another illuminating example comes from endurance racing, where teams utilize multi-strand tinned copper wire to enhance flexibility and durability. These wires are designed to resist the harsh vibrations and stresses faced during long races. Real-world testing in these high-stakes environments has shown that the lower resistance and superior conductivity of tinned copper result in better performance in the vehicle's electrical systems, from ignition to telemetry, ensuring that critical data is transmitted without losses. Such advancements highlight how the right choice of automotive wire can make a tangible difference in racing scenarios, underscoring the ongoing quest for performance optimization in motorsport.

Top 5 Examples of the Best Automotive Wire for High-Performance Applications

| Wire Type | Material | Temperature Rating | Maximum Current (A) | Application Examples |

|---|---|---|---|---|

| Silicone Wire | Copper | 200°C | 50 A | Racing ignition systems |

| Heavy-Duty PVC Wire | Copper | 105°C | 30 A | OEM applications, automotive lighting |

| Ultra-Flex Wire | Copper | 125°C | 55 A | Custom automotive builds, audio systems |

| High-Temperature Wire | Copper | 300°C | 70 A | Turbocharger applications |

| Teflon Wire | Copper | 260°C | 60 A | Motor sports, high-performance engines |

Industry Standards and Certifications for Automotive Wire: Ensuring Quality and Safety

When selecting automotive wire for high-performance applications, adherence to industry standards and certifications is crucial to guarantee both quality and safety. Key organizations such as the SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization) have established comprehensive guidelines that frame the manufacturing and testing of automotive wires. These standards help ensure that the wires can withstand extreme temperatures, resist corrosion, and maintain conductivity even under demanding conditions, which is essential for the reliability of high-performance vehicles.

In addition to SAE and ISO certifications, manufacturers often seek UL (Underwriters Laboratories) recognition for their wiring products. UL certification indicates that the automotive wire has passed rigorous safety tests, making it suitable for the automotive industry where failure could lead to serious safety hazards. Furthermore, adherence to these standards provides peace of mind to consumers and manufacturers alike, knowing that their performance and safety are backed by internationally recognized benchmarks. Thus, understanding and investing in certified automotive wire is not just a matter of regulatory compliance; it is an essential element in achieving optimal performance and safety in high-performance automotive applications.

Future Trends in Automotive Wiring Technologies for Enhanced Performance and Reliability

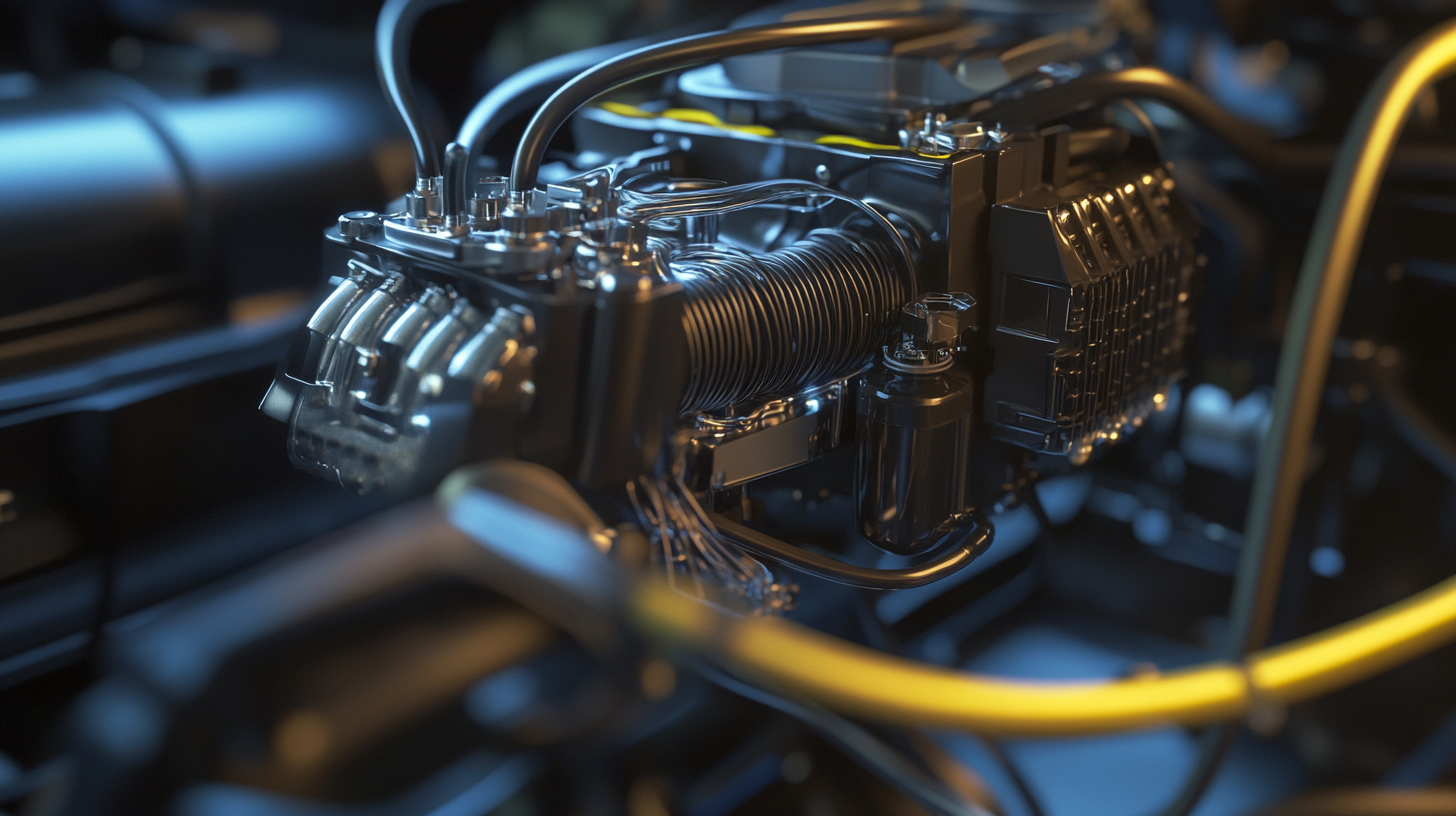

The automotive industry is witnessing a transformative shift, driven by the integration of advanced wiring technologies aimed at enhancing performance and reliability. As vehicles become more reliant on electronic systems, the wiring solutions must evolve to meet higher demands. One of the emerging trends is the use of lightweight materials, such as aluminum and specialized polymers, which significantly reduce overall vehicle weight, improving fuel efficiency without compromising on strength or durability. These materials enable high-speed data transmission while minimizing the risk of electrical interference, critical for modern high-performance applications.

Another key trend is the adoption of smart wiring harnesses equipped with sensors and diagnostic capabilities. These innovative systems can monitor the health of electrical components in real-time, alerting drivers to potential issues before they escalate, thereby increasing vehicle reliability. Additionally, the implementation of advanced coatings and insulation materials enhances resistance to harsh environmental conditions, which is essential for vehicles operating in extreme climates. The future of automotive wiring is set to focus not only on performance but also on sustainability, with a push toward recyclable materials and eco-friendly production processes, aligning with the broader industry movement toward environmental responsibility.