2026 Top Injection Machine Robot Trends and Innovations?

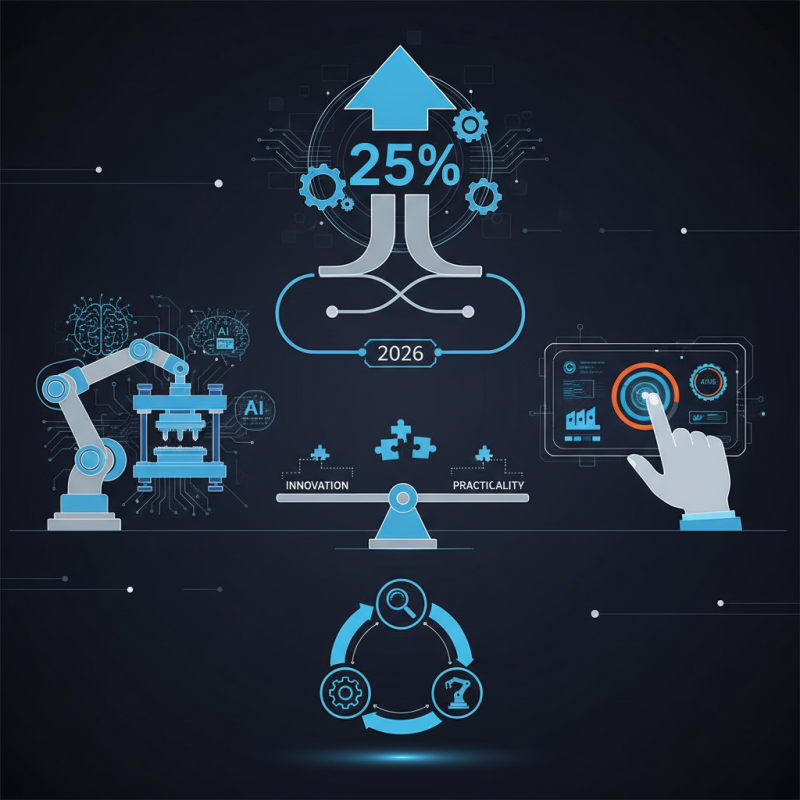

The field of Injection Machine Robots is evolving rapidly as industries seek enhanced efficiency. According to a recent report by TechNavio, the global market for injection molding robots is expected to grow by 25% annually. This surge signals a shift towards automation and smart manufacturing. Industry expert Dr. Emily Chang states, "The future of Injection Machine Robots lies in their adaptability and intelligence."

As manufacturers integrate advanced technologies, like AI and machine learning, the impact is profound. Robots are not just enhancing productivity; they are reshaping workforce dynamics. However, challenges remain. Many companies wrestle with integrating these systems seamlessly into existing workflows. A balance must be struck between innovation and practicality.

The demand for precision in injection molding presents a paradox. While technological advancements promise accuracy, the human element remains critical for quality control. The industry must reflect on how to harmonize these facets. As we approach 2026, the landscape of Injection Machine Robots will certainly transform, but the journey is fraught with complexity.

2026 Trends in Injection Machine Robots: An Overview of Innovations

The injection machine robotics industry is evolving rapidly. In 2026, automation will play a key role. According to a recent report, 40% of manufacturers will adopt AI-driven robots. This technological shift allows for precise control, enhancing efficiency by up to 30%. Robots will handle complex tasks, reducing errors in production lines.

New materials will also influence innovations. Recent studies show a 25% growth in demand for environmentally friendly plastics. Injection machines will adapt to these materials, prompting manufacturers to rethink their processes. As this shift requires investment, some companies may struggle. It’s crucial to assess capabilities before upgrading.

*Tip: Evaluate your current production needs. Consider gradual integration of new technologies. This approach minimizes risks and optimizes budget.*

The trend toward customization is notable. Machine learning algorithms will help tailor production runs. This flexibility will enable manufacturers to respond quickly to market demands. However, implementation can be challenging. Companies must invest in training and oversee the transition carefully.

*Tip: Prioritize employee training programs. Equip staff with skills necessary for advanced technology. A strong team will drive innovation.*

These innovations highlight the need for continuous reflection and adaptation in the industry. Embracing change does not come without difficulties, but the potential benefits are profound.

2026 Trends in Injection Machine Robots: Innovations Overview

This bar chart illustrates the projected trends in the top innovations within injection machine robots for the year 2026. The data reflects the anticipated growth in key areas such as automation, energy efficiency, and precision. Each category represents significant advancements expected to impact the industry.

Advancements in Robotics Technology Impacting Injection Molding Industry

The injection molding industry is undergoing a significant transformation due to advancements in robotics technology. Robots are becoming essential partners in this manufacturing process. They enhance both efficiency and precision. The integration of AI and machine learning allows robots to adapt to various tasks. This adaptability is crucial in a fast-paced environment.

With new sensors and smart automation, robots can perform complex tasks with minimal human intervention. For instance, robots now handle material handling, filling, and quality inspection more reliably. This means fewer defects and reduced waste. However, reliance on automation raises concerns. What happens if the technology fails? Such risks highlight the need for robust backup systems.

The growing trend of collaborative robots, or cobots, offers a solution. Cobots can work alongside human operators safely. They share the workload while enhancing safety. Yet, companies must ensure proper training. A lack of skills could hinder the effective use of these advanced robots. Overall, the impact of robotics on injection molding is profound, yet it requires careful consideration and ongoing adaptation.

2026 Top Injection Machine Robot Trends and Innovations

| Trend/Innovation | Description | Impact on Industry | Implementation Year |

|---|---|---|---|

| AI Integration | Utilization of artificial intelligence to enhance operational efficiency in injection molding. | Increases production speed and reduces waste. | 2026 |

| Collaborative Robots (Cobots) | Robots designed to work alongside human workers to enhance efficiency and safety. | Improves safety and allows for more flexible manufacturing processes. | 2025 |

| Automation | Full automation of the injection molding process to minimize human intervention. | Reduces labor costs and increases consistency in production. | 2024 |

| Data Analytics | Utilization of big data analytics to optimize production schedules and machinery performance. | Enhances decision-making and can predict maintenance needs. | 2023 |

| Sustainability Innovations | Adoption of eco-friendly materials and manufacturing processes. | Reduces environmental impact and meets increasing regulatory standards. | 2026 |

Key Market Players Driving Innovations in Injection Machine Robotics

The injection machine robotics market is evolving rapidly. A recent report estimates that the industry will reach $5 billion by 2026. This growth is primarily driven by increasing demand for automation in manufacturing processes. Key market players are pushing boundaries to introduce cutting-edge robotics solutions.

Automation enhances efficiency and precision. For instance, robotic arms now incorporate advanced sensors and AI. This allows machines to adapt in real-time. However, challenges remain in integration with existing systems. Some factories struggle to fully utilize new technologies. A lack of skilled personnel also limits progress in some regions.

Innovation is crucial. Emerging trends include collaborative robots, or cobots, which work alongside humans. These units are designed for smaller tasks. Their versatility can improve workflows significantly. Still, it's important to evaluate their long-term impact on the job market. Balancing innovation with workforce implications is essential for sustainable growth.

Data-Driven Insights: Efficiency Gains from Smart Injection Robots

The injection molding industry is rapidly evolving with smart technologies. Data-driven insights reveal that efficiency gains from smart injection robots can reach 30% or more. Companies leveraging these innovations report significant improvements in production speed and accuracy.

Smart injection robots utilize advanced algorithms and real-time data analytics. This technology optimizes the molding process, reducing waste and enhancing product quality. Reports show that defects can drop by 20% when using intelligent systems. However, not all organizations have embraced these advancements. Some manufacturers struggle with integration costs and technical training.

Cost constraints can impede innovation. It is crucial for companies to assess their long-term benefits against initial investments. While the promise of increased productivity is enticing, the transition requires careful planning. Many firms face challenges in adjusting their workflows to accommodate new robotic systems. Balancing efficiency with the human workforce presents an ongoing dilemma.

Sustainability in Injection Molding: Eco-Friendly Robot Solutions for 2026

In 2026, the injection molding industry is focused on sustainability. Eco-friendly robot solutions play a critical role in this shift. According to recent industry reports, over 70% of manufacturers are seeking green technologies. This includes energy-efficient robots that reduce waste and carbon footprints.

Many robots now use biodegradable materials in their construction. This innovation helps minimize the environmental impact during production and disposal. Additionally, technologies like AI optimize energy use, furthering sustainability goals. However, challenges remain. Not all manufacturers can afford these advanced robots. Transitioning older systems often leads to extra waste.

Tips for businesses:

1. Assess current machinery for eco-upgrades.

2. Seek partnerships with tech firms for sustainable solutions.

3. Invest in training for staff. Knowledgeable workers are key to successful implementation.

As we embrace these trends, the industry faces tough choices. Balancing cost, efficiency, and sustainability is no easy task. Continuous reflection on these decisions will guide future developments in injection molding.